Skunned Knuckles

Skunned Knuckles Articles

by Nail Maken

Cleaning Grease Fittings

The frame of a car or truck has a number of fittings which require lubrication. They are used in those areas where movement is necessary. These joints may be along the propeller shaft, the springs and the spring hangers, and especially in the front end the steering and the suspension.

Each of these parts must be maintained with proper lubrication - generally grease, but occasionally oil. Refer to the owner’s manual or service manual for location and the type of lubrication which is recommended for each moveable joint. Fresh grease must be forced, through the pressure of a grease gun, into each of the fittings in order to lubricate the moveable joint.

Old grease dries out and gets hard. Often rock hard! When that occurs, it is impossible to force new, fresh grease into the joints that require lubrication. Solving the problem means either replacing the grease fitting with a new one, or cleaning the grease out of the old fitting.

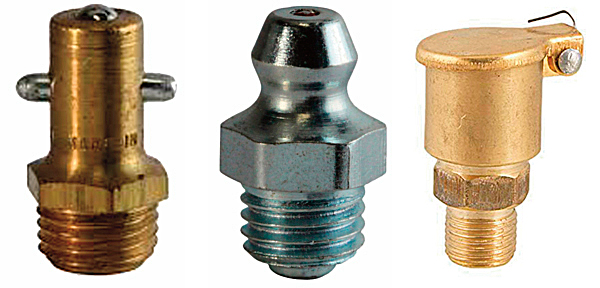

Essentially, there are three common grease fittings used on older vehicles: grease cups, Alemite pin fittings, and Zerk fittings. All experience the same problem with old grease hardening and clogging the fitting.

Left to right: Alemite Pin Fitting, Zerk Fitting, Grease cup

If, when trying to use a grease gun to force fresh grease into the joint through the grease fitting, fresh grease does not appear at the joint, it is probable that the fresh grease is being blocked and not getting through to the joint.

All three types of fittings are screwed into the joint. Careful examination of the fitting, after using a wire brush, solvent and a rag to clean the fit-ting, will show a hex as part of the fit-ting itself. An open-end wrench will remove the fitting from the joint.(Alemite pin grease fittings may have a dust cap which has to be removed to access the fitting itself.)

Generally soaking the fitting in solvent at this point will not be a satisfactory method of softening the old grease. Begin by removing as much of the old grease with a small screwdriver and a piece of wire. You will be able to remove most of the visible grease from the bottom of the fitting. Because of the construction of the Alemite and Zerk fittings you will not be able to get the wire through the fitting. A spring and a check-ball seal the opening, preventing the grease from escaping out of the top of the fitting.

A spring and check-ball prevent the grease from escaping from the fitting.

After as much of the old grease is re-moved, heat the fitting with a hair dryer or a heat gun (set on low). When the grease is softened with the heat, immediately apply a grease gun to the fitting with fresh grease. While softened, the old grease will be forced out and the fresh grease will displace it.

The grease cup can be cleaned by cleaning out the old grease, and using a wire to remove the old grease from the screw-in end of the grease cup. Wash the grease cup with a solvent and wire brush and piece of wire.

Originally printed in Skinned Knuckles magazine, and copyrighted by SK Publishing/Skinned Knuckles Magazine. Reprinting of any portion prohibited without written permission of SK Publishing, PO Box 6983, Huntington Beach, CA 92615.

Subscriptions to Skinned Knuckles magazine is $28.00 for twelve monthly issues (within the U.S.). Contact Skinned Knuckles by mail at PO Box 6983, Huntington Beach, CA 92615; Website skinnedknuckles.net and click on Subscribe or PayPal. E-mail sk.publishing@yahoo.com, phone: 714-963-1558.