Skunned Knuckles

Skunned Knuckles Articles

by Skinned Knuckles Magazine

What is Freewheeling?

Today, most of our contact with free wheeling units comes when we take our bicycles out for a ride. We pedal to get the bike up to speed, and then relax while the bike coasts. This is especially noticeable when coasting down a long, moderate incline. Wheel speed and gravity keep the bicycle moving steadily while we, the riders, sit back and enjoys the scenery. There is really no liability to this exercise, especially if our bicycle has hand-operated brakes. The grasp ing of the brake handles pulls a cable which brings two friction pads against the wheel rim, slowing , and eventually stopping the bike. Braking is done totally independently of the power source - the pedals.

The freewheeling hub was, in fact, developed for bicycle use, but in the early 1930s it was adapted for automotive use. Most automobile manufacturers looking for something to make their car sound better, brighter, shinier and to appeal to more people in a very competitive mar ket, added a freewheeling system to the car's transmission. The freewheeling was touted as an economy measure. The car would be more fuel efficient if the engine could ' idle' while maintain ing road speed. But one of the liabilities was that a 3,000 or 4,000 pound car had a lot more inertia than did a 70 pound bicycle. Speeds were generally greater, and these factors made it more difficult for the brakes alone to stop the car without suffering damage. But the downside of the free wheeling was not mentioned by the car-makers. It was another feature that manufacturers could add to their machines to make them more appealing to the customer.

Before we get much further into the subject, though, let's clear up one misconception. Freewheeling is not synonymous with 'Overdrive.' An overdrive unit will contain a freewheeling system, but a basic freewheeling unit is not and does not constitute freewheeling. Basically an overdrive unit allows the drive shaft (and then the rear end and rear wheels) to tum faster than the revolutions of the crankshaft. Because of the lower gear ratio of overdrive, the car produces less torque, but more economical cruising. A series of gears lowers the ratio of engine-to-driveshaft revolutions to less than 1:1. With the overdrive engaged, the rear wheels are allowed to tum faster than the revolutions produced by the engine, thus giving better, low torque economy. The overdrive system is sophisticated enough, though, that when road conditions demand - for hill climbing, passing speed, or lower road speeds (generally below 40 mph), the gear shift within the transmission/overdrive unit is virtually instantaneous, switching from the (almost) coasting condition to a ratio which allows the engine speed to more closely match that of the driveshaft.

But back to freewheeling. Whereas over drive selects a lower ratio gear when suitable, freewheeling has to be manually engaged or dis engaged by the driver. By engaging the free wheeling, essentially the engine is mechanically disconnected from the rear wheels so that the road speed - the revolutions of the rear wheels - determines the speed of the car, not the revolutions of the engine. At lower speeds, speeds at which the engine revolutions equal or exceed the rotation of the driveshaft, a mechanical ' lock' keeps the engine/driveshaft in contact with each other. But as the rear wheels/driveshaft reach speeds where the driveshaft rotational speeds exceed that of the engine, the freewheeling unit disengages the two components allowing the car to coast. Now here is the problem. Normally, the engine, when the driveshaft speed exceeds the crankshaft speed, exerts a drag on the transmission of power, slowing the driveshaft speed (through a pre-determined ratio of gears - 2nd gear, 3rd gear) down to the engine speed. As the engine slows further, when climbing hills or when fuel is reduced to the carburetor, the rear wheels follow. The drag of the engine helps slow the forward speed of the car, assisting the brakes.

But with freewheeling engaged, it is essentially like driving with the clutch depressed. (In Australia - and perhaps other places - this is known as ' Angel Gear ' because it brings the driver that much closer to the angels.) The engine speed and the rear wheel speed become independent of each other. This occurs at a minimum speed, so generally high gear (third or fourth gears) is the only one involved, but it could reasonably happen in second gear, too, if adequate speeds can be obtained with the second gear ratio. When the rear wheel speed exceeds the crankshaft rotational speed and the engine/drive shaft are ' disconnected', the car becomes a run-away. It is the rear wheels that determine the car's speed, not the engine. The only control that the driver now has is with the brakes and with the steering. Steering generally has nothing to do with forward speed unless the driver steers the car up a hill or into an oak tree.

The brakes, especially on our older cars, were adequately sufficient. They normally did a reasonably good job of slowing and stopping the car. But when exposed to ultra-demanding situations - like a 4,000 pound car barreling down a hill in freewheeling • the brakes are working beyond their normally anticipated capabilities. Overheating, or even outright fire, can be the result. Remember, letting your foot off the gas pedal will not slow the car when it is in freewheel ing; the engine is 'disconnected.'You're flying on a wing and a prayer. You had best hope that 1) the downhill road takes an upturn, 2) there are no hair pin turns ahead of you, 3) special conditions • like an on-coming car • don't demand a rapid stop, or 4) 1hat oak tree doesn't jump out in front of you. Driving in hilly terrain became an 'E' ride.*

Okay, that's the bad stuff about free wheeling. What are the advantages? (This will be a much shorter paragraph.) Fuel economy. Alright, maybe minimally less wear on the engine. And the ability to shift gears without depressing the clutch. But the freewheeling is only engaged when the driveshaft is turning faster than the engine - on a downhill road. How often does that occur? The fuel economy and reduced wear on the engine happens in free wheeling because the engine drops down to an idle while coasting down the hill. (Theoretically freewheeling will help as well on flat roads where coasting is possible. But without inertia, the car will slow down and it will take extra gas and extra 1pms to bring it back to 'coasting' speed.)

Reduced control was the biggest problem with freewheeling, and the increased fuel economy? Well, nothing to write home about. After the late 1930s or so, freewheeling became a footnote in automotive history. And it was about the same time that overdrive became popular and within not too many years, almost a standard part of the automotive transmission.

By giving the car more gas-increasing the engine's rpms – once the engine speed matched the driveshaft speed, the freewheeling would disengage. But, unless the freewheeling was locked out, when rear wheel speed I again exceeded input shaft speed, you were back in freewheeling mode.

HOW DOES FREEWHEELING WORK?

The simplest visual analogy is a ratchet; a sawtooth gear working against a pawl. If you can imagine that when the sawtooth gear spun fast enough, the pawl would be locked out eliminating the slowing or stopping attributes, that's a freewheeling unit.

The simplest visual analogy is a ratchet; a sawtooth gear working against a pawl. If you can imagine that when the sawtooth gear spun fast enough, the pawl would be locked out eliminating the slowing or stopping attributes, that's a freewheeling unit.

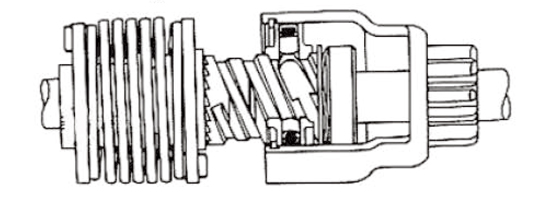

A number of different systems were used to actuate a freewheeling unit, but essentially they were all very similar: An over-turning clutch system disengaged the driving shaft (from the engine/transmission) from the driven shaft (drive shaft or propeller shaft).

In most cases an outer sleeve, geared internally, would be fitted with an inner cam. Roller bearings held in place between the teeth of 1he inner cam would engage with the outer sleeve connecting the sleeve and 1he cam, and thereby connecting 1he engine/transmission with the driveshaft/rear wheels. As the rear wheel speed increased to a point that driveshaft revolutions exceeded the input shaft revolutions speed, the roller bearings would be thrown out of engagement with the outer sleeve, allowing the inner cam to spin freely. As the rear wheel/driveshaft speed declined, the rollers would then reengage with the outer sleeve.

In most cases an outer sleeve, geared internally, would be fitted with an inner cam. Roller bearings held in place between the teeth of 1he inner cam would engage with the outer sleeve connecting the sleeve and 1he cam, and thereby connecting 1he engine/transmission with the driveshaft/rear wheels. As the rear wheel speed increased to a point that driveshaft revolutions exceeded the input shaft revolutions speed, the roller bearings would be thrown out of engagement with the outer sleeve, allowing the inner cam to spin freely. As the rear wheel/driveshaft speed declined, the rollers would then reengage with the outer sleeve.

OTHER APPLICATIONS

Now having bad-mouthed freewheeling, let me backtrack and give an example (or two) of how freewheeling is used in both our older (mid- 1920s) and newer cars - the starter motor engagement. In most cars, the starter motor Bendix gear is an example of an over-riding clutch or free wheeling gear.

When the starter switch is first engaged, electricity flows to the starter motor and the motor begins to spin. A gear on the end of the starter motor's center shaft is thrown, through centrifugal force, to a point where the gear locks onto the shaft and engages with the flywheel. The torque of the starter motor spins the gear, which in tum spins the flywheel. As the engine starts, the gear must be disconnected from the flywheel or it will quickly destroy the starting motor. The gear goes into a freewheeling mode in which it is disengaged from the starter motor shaft, and allowed to spin freely, and, at the same time, is thrown free of the flywheel. That's it! Freewheeling in action.

Occasionally the Bendix gear sticks and doesn’t engage. The constant whining sound that you hear is the starter motor being driven by the revolutions of the flywheel. Even though no electrical power is going to the starter motor, the motor is spinning, driven by the locked-on gear still engaged with the flywheel. This conditions is most often caused by two faults. First, and most general, is a bad tooth (or teeth) on the Bendix gear, or less frequently on the flywheel ring gear. The bad tooth (teeth) hold the Bendix gear in con tact with the flywheel. Removal of the starter motor and examination of the Bendix gear will often indicate the problem tooth/teeth. If you find a bad tooth on the Bendix gear, a careful tooth-by tooth examination of the flywheel is called for. Sometimes it can be done through the starter motor mounting hole. Other times removal of an examination cover will expose a larger section of the fly wheel ring gear. If the ring gear is damaged, it calls for replacement. Often, especially on popular old car models, a ring gear will be an in-stock item. On rarer or less common cars, a ring gear may have to be fabricated or located through a specialist. Al Suehring (715-677-3809, al@suehring.com) specializes in ring gears. Contact him first.

Finally, Studebaker used an over-riding clutch assembly for their starter motors in the mid-1920s. The starter motor engaged a gear box located at the front of the starter motor which increased the torque of the starter motor immensely. That gear train engaged a chain (with a sprocket) and the chain spun the front of the crankshaft rather than the flywheel at the rear. At the engine end of the chain was a second sprocket, part of a clutch assembly. As the starter motor drove the chain/sprocket assembly, the clutch engaged with a series of three pawls. When the engine started, the pawls would release and dis engage the clutch. Simple but effective, and another example of the principle of freewheeling put to good use.

?

Originally printed in Skinned Knuckles magazine, and copyrighted by SK Publishing/Skinned Knuckles Magazine. Reprinting of any portion prohibited without written permission of SK Publishing, PO Box 6983, Huntington Beach, CA 92615.

Subscriptions to Skinned Knuckles magazine is $28.00 for twelve monthly issues (within the U.S.). Contact Skinned Knuckles by mail at PO Box 6983, Huntington Beach, CA 92615; Website skinnedknuckles.net and click on Subscribe or PayPal. E-mail sk.publishing@yahoo.com, phone: 714-963-1558.