Skunned Knuckles

Skunned Knuckles Articles

by Orest Lazarowich

Linkage Steering Power Assist

This steering system uses a manual steering gear with a linkage steering assist. It is a simple and efficient system developed by the Bendix Corporation and was used by many Ford vehicles (1958-1980) including Mustang. The Saginaw division of GM produced a linkage steering assist for some mid-fifties GM applications, and Corvette used a linkage power assist from 1963 to 1982. The linkage assist steering consists of three hydraulic components that work together to steer the vehicle. The positive displacement pump, the hydraulic control valve and the hydraulic cylinder which is constructed of one tube inside the other. The pump is belt driven and provides hydraulic fluid under pressure. These three components are connected together with hydraulic hoses which carry the pressurized power steering fluid (PS fluid) through the system.

General Motors 1955-1959 linkage-type power steering was available as a regular production option on many models. Fingertip steering control was provided by the hydraulic system which greatly reduced the need for ‘horsing’ the steering wheel.

The control valve receives input signals from the steering wheel. Left or right steering causes the valve to react, opening ports to move power steering fluid into the cylinder. PS fluid directed to one side of the cylinder piston or the other determines which direction the power assist will apply. The hydraulic cylinder attaches to the steering linkage and the rod coming out of it attaches to a bracket mounted on the drivers’ side frame rail. The end of this rod goes inside the inner tube of the cylinder and has a piston attached to its end which pushes or pulls the steering linkage in the proper direction. The vehicle can be steered manually when the engine is not running. A pres-sure relief valve in the pump protects the system from excess pressure when the engine is turning at high speeds. A disadvantage of this system is that the hydraulic cylinder and hoses are exposed to the elements and road debris. Power steering fluid leaks are more common.

POWER STEERING PUMP

There are three different types of power steering pumps (PS pumps) used in the power steering system: vane, slipper or roller. They all contain a cam ring with a cam-shaped inner opening. A rotor turns inside the cam ring. The difference is in the design of the fins that move the PS fluid inside the pump. The vane type PS pump is the most common. In this type of pump the rotor is housed in an oval or elliptical shaped housing. As the rotor turns, the vanes are thrown out against the housing walls by centrifugal force. When PS fluid enters into the vane pump housing it is trapped between the vanes, the housing wall and the rotor. Pressure is built up to the required level, and this high pressure fluid is pumped out of the housing into the hose that leads to the hydraulic cylinder. If too much pressure is built up, the relief valve opens and allows some of the PS fluid to return to the reservoir.

A typical vane-type power steering pump indicating the primary components of the pump.

In the roller PS pump the PS fluid enters the pump and is pressurized by the rotating motion of the roller and the elliptical pressure chamber. Wide V-grooves are cut into the rotor and steel rollers ride in these grooves following the inside contour of the cam ring. The rollers trap the power steering fluid, pressurize and release it. A pressure valve with an internal relief valve controls the maximum pressure and prevents excessive pressure build-up when the vehicle's wheels are turned full lock. This style of pump has been used on a variety of vehicles including American Motors, Ford, General Motors and Studebaker.

The slipper type PS pump is similar to the roller type except it uses spring loaded scrubbers (slippers) fitted into wide slots on the rotor. The springs keep the slippers in constant contact with the cam ring. As PS fluid enters the pump, pres-sure is built up and released to drive the power steering system. A flow control valve and a relief valve are located in the housing. Many Ford products use this style of pump, and it has also been used by Chrysler.

HYDRAULIC CONTROL VALVE

The hydraulic control valve is attached to one end of the center link and to the Pitman arm. It receives pressurized fluid from the pump and directs it to one side of the hydraulic cylinder causing the wheels to turn in the desired direction. In straight ahead driving position the control valve is in neutral position. The control valve consists of two parts: the ball stud sleeve and the valve housing. The ball stud sleeve connects to the center link (drag link) and bolts on to the valve housing. Pressure from the Pitman arm tips the ball stud activating the control valve. Inside the housing is a spool valve that slides and covers or uncovers passages in the housing that sends pressurized fluid through hoses to the hydraulic cylinder.

HYDRAULIC CYLINDER

This is a double-acting hydraulic cylinder as pressurized fluid is admitted at the end of the cylinder to provide force in both directions. A movable piston and rod slides in the cylinder housing in response to which hose the control valve sends pressurized fluid to. One end of the rod is fastened to the piston, and the end that comes out of the cylinder is attached to the frame rail of the vehicle. When the piston and rod move back and forth they alternately push and pull against the frame of the vehicle. Since the cylinder is connected to the center link the steering linkage moves back and forth turning the wheels and the vehicle. Some models use a hydraulic cylinder that is combined with a control valve.

TROUBLESHOOTING POWER STEERING

Inflate the tires to correct pressure. Drive the vehicle. Does the problem occur only when the system is hot or cold? Does the problem only appear when turning in one direction? Does the problem only appear in a certain spot while turning the steering wheel? Check for a loose power steering belt first. A loose belt will slip causing belt squeal and erratic steering effort. If the belt is okay, check the steering linkage. If there is excessive free play at the steering wheel, check the tie rod ends, drag link, Pitman arm, king pins, ball joints and steering column. Excessive wear will cause high steering effort, front end shimmy and over steering. Steering gear must be tight to the frame. If there are no signs of excessive wear, lubricate the front end grease fittings. Adjust the steering gear. Check the power steering linkage. Examine the hydraulic cylinder and control valve for leaks and road damage. PS fluid leaking from the stretch boot where use indicates the seals are damaged in the hydraulic cylinder. Leaks at the control valve maybe caused by hardened spool seals or by a pitted spool valve. The hoses are subject to stretching and flexing as the hydraulic ram and steering linkage move back and forth. The hoses should be flexible and have no kinks in them. When they become hard or soft, cracked, abraded or leaking, replace them. Remove the hoses by unscrewing them using a tubing wrench on the fittings.

POWER STEERING FLUID

A common problem is PS fluid leakage. The developed pump pressure can cause leaks around the fittings, the hoses, the pump seals or at the hydraulic cylinder and control valve. Wear eye protection when checking the power steering system with the engine running. Wipe the leaking area with a clean cloth. Have a buddy start and idle the engine. While watching for leaks have him turn the steering wheel to the right and left. This action pressurizes the system. Locate the leak and repair it on the vehicle (hoses) or remove the part and repair or replace it (hydraulic cylin-der, control valve, pump). Fluid levels must be maintained between the MIN and MAX lines when the PS fluid is at operating temperature. Add to the MAX line only when the engine is cold. Automatic transmission fluid (ATF) is used in the power steering systems of the vehicles we are concerned with. Newer systems may require a special PS fluid. Refer to the owners manual for the correct type of fluid.

POWER STEERING FLUSH

PS fluid breaks down over time and should be replaced. When the color starts to dark-en from a pinkish color or has a burnt smell the PS fluid should be replaced. The burnt smell can be caused by low PS fluid level or containment buildup. Metallic glitter in PS fluid is a sign of the pump starting to fail. The darkening of the PS fluid can be caused by the deterioration of the power steering hoses. They start to break down from the inside sloughing bits of rubber material into the PS fluid and causing it to darken. Draw a sample out of the reservoir with a turkey baster and spread it out on an absorbent paper towel. What is left on the towel after the fluid is absorbed is the contaminant. Change the fluid.

If the hoses are hard or spongy, replace them and then flush the system. Raise the front of the vehicle on safety stands so the wheels clear the floor. Buy a couple of quarts of automatic transmission fluid. Check the service manual for the proper type. Remove the reservoir cap or lid. Remove the return line from the reservoir and drain the reservoir. Plug the return tube. Place the return hose in an empty plastic milk container. Dispose of the old oil at a recycling center. Have a buddy start the vehicle with the transmission in Neutral. With the engine running pour automatic transmission fluid into the reservoir. Have your buddy turn the steering wheel right to left; left to right until clean fluid runs out the return line. Do not run the reservoir dry. Shut off the engine.

Reconnect the return line and fill the reservoir to the correct level. If this line uses a one time clamp, replace it with a screw type clamp. Install the cap or lid. Cycle the steering wheel lock to lock a few times to bleed the air out of the system. This forces the air into the reservoir and out of the system. This procedure can vary for dif-ferent vehicles. Consult the service manual for your particular vehicle. Air can cause the power steering system to make a buzzing sound when the steering wheel is turned right or left. Do not apply any force when the steering wheel is at lock position. This can damage the pump. Check the fluid level, and add as needed. If air continues to get into the system, check the pressure hose for leaks. Lower the vehicle. Check the front tire pressure. Road test. If you find that it takes increased steering effort to steer the vehicle or the steering wheel jerks when turning a corner, the power steering pump may be at fault.

POWER STEERING PUMP

If there are no leaks and the fluid level is correct and the belt is adjusted properly, start the engine and listen for pump noise. If you hear a growling (whine) noise when the system is up to temperature, it is an indication that the power steering pump will soon need service. Stop the engine, and remove the power steering belt. Check the power steering pump pulley for end play and side-to-side movement.

Replacing the seal on a pump that is starting to fail will only give you the experience of removing the pump twice.

There should be no movement. If there is PS fluid leaking from the front seal and some side-to-side movement of the pump pulley, repair/replace the pump. Replacing the seal on a pump that is start-ing to fail will only give you the experience of removing the pump twice.

If you are not sure of your diagnosis, the PS system can be checked for internal leakage with a pressure test. You will need an in-line pres-sure gauge with a shutoff valve and the correct fit-tings (adapters) to plumb the gauge into the pres-sure line.If you do not have the proper equipment, have a service center do the test. They will test the pressure created by the pump, control valve and the pressure relief valve. If the readings are not within specifications, the power steering pump is weak and must be replaced.

Most pumps mount near the top of the engine. Some early styles are powered by the generator. For this style check www.larescorp.com for pump rebuild services. Drain the PS fluid into a container by removing the hoses from the pump. Remove the drive belt and inspect it. Replace it if necessary. Remove the bolts that hold the pump to the engine, and remove the pump. Replace the old pump with a new or rebuilt (exchange) pump. It may be necessary to transfer the pulley from the old pump to the new one. Make sure the old pulley is not bent or cracked. Mark the position of the old pulley before you remove it. You need a special puller to remove/install the old pulley. Do not try some Rube Goldberg contraption. You will damage the pulley. To replace the pulley it must be pulled into place. The parts center may provide this service when you purchase the pump. Once the pump is installed, the system has to be bled of trapped air. Consult the service manual for your particular vehicle. Road test.

CONTROL VALVE

The location of the control valve and hydraulic cylinder under the vehicle can cause damage to the control valve and the hydraulic cylinder or rod by road debris, off-road driving or an accident. Weather conditions such as rain can allow water to enter the control valve and cause rust corrosion. This causes the valves inside to rust and pit and in time seize up causing erratic steering. The rod may have corrosion pits or deep scratches which will damage the seal and cause a fluid leak. If the rod is damaged, replace the hydraulic cylinder at the same time you service the control valve. If the rod is smooth but leakage is evident, order a seal kit and rebuild the cylinder. If more steering effort is required in one direction than the other, adjust the control valve to try and correct this problem. If there are any fluid leaks, they must be repaired first. Follow the service manual for proper procedure. The following is a general procedure only. Wear safety glasses. Have the wheels in a straight ahead position. Raise the front so the wheels are off the ground, and set the vehicle on safety stands. Locate the cover on the outside end of the control valve. Remove the cover, and locate the adjusting nut. You will have more room to work in if you remove the left front wheel.

Start the engine. If the piston rod does not move, turn the adjusting nut clockwise until the rod starts to move outward. Do not get your arms caught in the steering linkage. Now, turn the nut counterclockwise, and count the number of turns it takes until the rod starts to move inward. Then turn the nut clockwise to exactly one-half the dis-tance to change the piston rod direction. If the pis-ton rod does start to move outward when you start the engine, turn the adjusting nut counterclock-wise until the rod starts to move inward. Then, turn the nut clockwise until the rod begins to extend. Turn the nut counterclockwise exactly one-half the rotation needed to change the piston rod direction. The nut is self tightening, and if you think it might slip, add a bit of thread lock. Shut off the engine. Put the cover and wheel on, and lower to the ground. Check fluid level. Restart the engine. The front wheels should not move in either direction from the center. If they do, the valve adjustment is incorrect, and the procedure must be repeated. If the valve adjustment does not balance the control valve, it will have to be removed for disassembly and inspection.

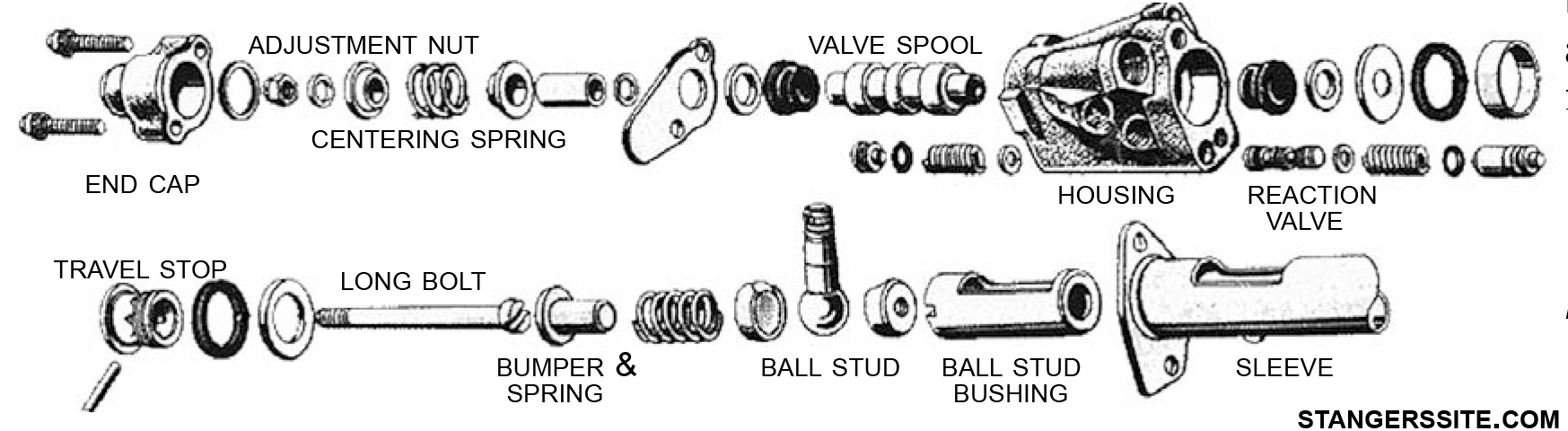

Parts of a typical power steering control valve.

CONTROL VALVE REMOVAL BENDIX STYLE

Raise the front of the vehicle on safety stands. If the vehicle is on a hoist, adjust the height of the hoist so you can work comfortably. Disconnect the pump-to-control valve hoses and drain, then disconnect the valve-to-hydraulic cylinder hoses, and drain into a suitable contain-er. Discard the fluid. Loosen the clamp bolt. Remove the roll pin from the steering arm-to-idler arm rod through the hole in the sleeve. Disconnect the Pitman arm from the ball stud.. Remove the cotter key and then the nut. Use a ball joint splitter to separate the ball joint. Do not use a ‘pickle’ fork to loosen the ball joint because it is possible to pull the ball stud out of the control valve. Turn the front wheels fully to the left, and remove the control valve. Count the number of turns it takes to remove the control valve from the center link. Screw the new valve in the same number of turns. This should center the steering wheel. Remove the hydraulic cylinder.

CONTROL VALVE DISASSEMBLY

Refer to the service manual for disassembly/assembly procedures. Wash the outside of the control valve and blow it dry. Work in a clean area, and disassemble the control valve starting from the end cap. Count the number of turns to remove the adjusting lock nut. Remove the valve to adapter bolts, and pull away the valve housing and spool. Remove the spool. Remove all the other parts from the adapter, and keep them in order. Turn the adapter plug out of the adapter sleeve. Turn the adapter upside down, and the spring and one ball seat will fall out. Now remove the ball stud, the other ball seat and the ball stud boot. Keep the parts in order, and wash the parts in clean solvent, blow them dry, and examine them for wear, corrosion and damage. The spool valve and the control valve housing bore MUST be in good condition. If the spool valve surfaces are scored, it must be replaced. Carefully check the seal surfaces. If they are pitted or show signs of corrosion, the valve must be replaced. Very light corrosion can be removed from the valve spool bore with crocus cloth. If you can not purchase a new spool valve and the control valve housing bore has deep pits in it, your next move should be a rebuilt exchange unit.

CONTROL VALVE ASSEMBLY

Order a standard rebuild kit which will contain gaskets, seals and O-rings, if the control valve can be rebuilt. Follow the service manual procedure, and use clean PS fluid to lubricate the parts during assembly. Turn the adjusting lock nut in the same number of turns it took to remove it. When the control valve is assembled cover the ports, and paint the valve gloss black. When dry install the control valve, and turn it in the number of turns necessary, then lock it in place. Assemble the ball stud to the Pitman arm. Don't forget the cotter pin. Reconnect the ball stud at the relay rod, and install the nut and cotter pin. If there is any doubt about the condition of the hoses, replace them. Start the hoses by hand at least for 3 or 4 threads, and then use the tubing wrench. Fill the pump with fluid, and bleed the air out of the system. If necessary, balance the valve as previously noted. Road test.

HYDRAULIC CYLINDER SERVICE

Raise the front of the vehicle on safety stands. Mark the location of the hoses to assist during reassembly. Disconnect the hoses and cap the ends. Clean the threads at the frame bracket end, and remove the cotter pin, nut, retainers and bushing. Inspect the thread and the rod for corrosion at this end. Disconnect the ball stud end using a ball joint splitter. Remove the hydraulic cylinder for inspection and repair. Drain the fluid, and dis-pose of it. Remove the stretch boot. Replace it if it is torn. Clean the outside of the hydraulic cylinder to inspect for cracks in the tubing. If you feel a rough spot when the rod is moved in and out, there is corrosion in the inner tube caused by water which has entered past the seals. This corrosion will damage the piston seal so that it will not seal the inner cylinder. The cylinder will not provide full pressure to the steering linkage because the fluid leaks past the seal. If the rod binds when moving it in or out or the chrome surface is pitted or corroded at the mid section or at the bracket end, replace the cylinder. Check the ball stud.

The construction of the hydraulic cylinder does not permit repairing the cylinder, piston or the rod. If these parts are damaged, replace the entire assembly with a new or rebuilt (exchange) hydraulic cylinder. Seals and hose seats can be replaced. Order the correct rebuild kit. Clamp the hydraulic cylinder in a vise facing the rod upward. Remove the snap ring, and pull the rod outward to remove the dust seal and washer. Use a seal pick, and very carefully draw out the seal. Do not scratch the rod or the inside edge of the cylinder. Lubricate the new seal with AT fluid, and install the seal, retainer and dust seal using a 7/8" deep socket. Install the washer and the snap ring. If hose seats are included in the kit, use a 3/8" starting tap to cut threads in the old seats. Blow the chips out after tapping. Make up a puller using a large washer and a 3/8" bolt. Lubricate the new seats, and press them in place using the power steering hose that connects to the cylinder. When you sense the seat has bottomed stop.

Slip the stretch boot over the rod, and position the cylinder rod on the frame bracket and replace the bushing, retainer, nut and cotter pin. Pull back the cylinder, and install the other end of the cylinder in the center link. Replace the castel-lated nut, and install a new cotter pin. Secure the stretch boot. Reconnect the hoses in their respec-tive ports, and do not over tighten the fittings. If you do, you will crush the seats and leaks will occur. Fill the PS reservoir with clean PS fluid, and start the engine. Bleed the air out by turning the steering wheel lock-to-lock several times. Check for leaks. Hopefully none. Check the fluid level, and add to the proper level. Lower the vehicle. Road test.

HAPPY MOTORING.

Originally printed in Skinned Knuckles magazine, and copyrighted by SK Publishing/Skinned Knuckles Magazine. Reprinting of any portion prohibited without written permission of SK Publishing, PO Box 6983, Huntington Beach, CA 92615.

Subscriptions to Skinned Knuckles magazine is $28.00 for twelve monthly issues (within the U.S.). Contact Skinned Knuckles by mail at PO Box 6983, Huntington Beach, CA 92615; Website skinnedknuckles.net and click on Subscribe or PayPal. E-mail sk.publishing@yahoo.com, phone: 714-963-1558.