Skunned Knuckles

Skunned Knuckles Articles

by Orest Lazarowich

Manual Steering Gear And Linkage

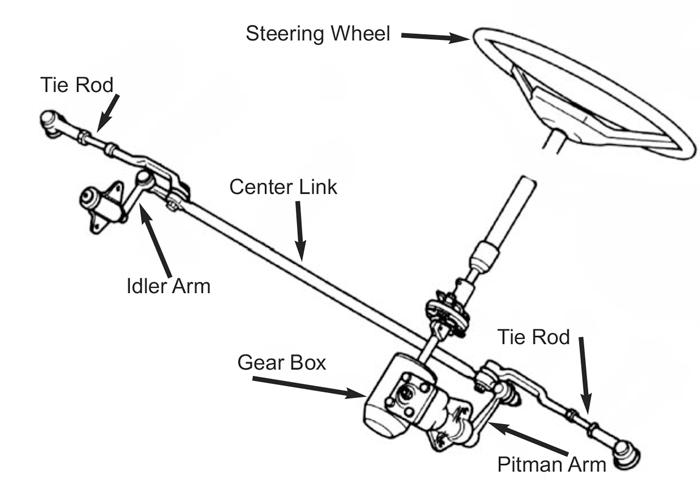

The steering gear mechanism allows the driver to turn the front wheels of the vehicle. This includes the steering wheel, steering gear box, pitman arm, drag link, tie rods, steering arms, and steering knuckles which support the wheels. Turning the steering wheel left or right turns the steering shaft to which a worm gear is attached within the gear box. The steering worm gear moves the sector gear, and this motion is transmitted to the pitman arm which moves fore and aft. A drag link connected to the pitman arm transmits this movement to the tie rods which are connected to the steering arms. The steering arms turn the steering knuckles and the wheels which are pivoted left or right on the front end suspension.

There are four common manual steering gears in use. The worm and sector, worm and roller, recirculating ball steering and the rack and pinion. In the worm and sector style the worm is connected at the end of the steering shaft. The sector is mounted on a sector shaft. The teeth of the worm mesh with the teeth of the sector. The friction value is very high in this design because most of the load is concentrated on the gears at their mesh point. The worm and roller is similar to the worm and sector type. A toothed roller is mounted on a roller shaft, and a worm gear is mounted on the steering shaft. Gear teeth of the worm gear mesh with the roller, and motion is transmitted. The roller is mounted on a ball bearing. This bearing provided low friction as it took the load, and the roller distributed the wear more evenly. The recirculating ball steering offers extremely low friction and power loss. A ball nut on bearings is meshed with the worm gear and screws up and down relative to the movement of the worm. The rack and pinion steering consists of a pinion attached to the steering shaft which meshes with a flat rack. The pin-ion travels left or right on the rack to move the road wheels.

Steering linkage arrangements vary de-pending upon need and basic design. There are two basic types of steering control systems; those that have a pitman arm and a steering box, and those that use rack and pinion steering. The most common type of steering using a pitman arm is the parallelogram type. It uses two tie rods and a center link between the tie rods There is an idler arm on the passenger side and the pitman arm on the driver’s side that attach to the center link. When the steering wheel is turned the center link transfers the movement to the steering arms and outer tie rods. All of the joints which mount these components use small ball joints to provide the freedom of movement. The two sides of the linkage run parallel to each other and are equal in distance thereby forming a parallelogram steering linkage. In the rack and pin-ion system the center rod is replaced with a steering rack which is a long, toothed bar with tie rods attached to each end. On the end of the steering shaft there is a pinion gear that meshes with the rack. When the steering wheel is turned, the pinion gear turns, and it moves the rack from left to right. Changing the size of the pinion gear changes the steering ratio.

ROAD TEST

During the road test, listen for any unusual noises related to the suspension and steering. Check for steering problems such as: steering wander or drift, high steering effort and binding, excessive steering wheel free play, steering wheel return and front wheel shimmy. Back at the shop raise the front of the vehicle on safety stands. Inspect for worn suspension parts and/or worn tires. Hard steering can be caused by damaged steering linkage, worn steering linkage, damaged spindles and bent steering arms causing incorrect turning angles. Front tire shimmy can be caused by tire imbalance and/or tire runout. Vehicle instability can be caused by driveline misalignment, drive-line imbalance or unequal weight distribution be-tween the wheels. Inspect the shock absorbers or struts for loose mounting bushings and bolts. Ex-amine for leaks. Inspect the wheel bearings for lateral movement. Inspect the steering linkages and tie rod ends for wear (looseness). Inspect for loose steering gear mounting bolts, worn mounting brackets and bushings. Replace worn parts, and/or adjust front wheel bearings.

MANUAL STEERING GEAR

The gearbox is attached to the frame, and it can be directly connected to the steering shaft and wheel or by a U-joint/rag joint. Check for excessive free play (more than 1½ - 2") at the steering wheel. Check the steering shaft U-joint/rag joint for wear, if the steering gear is of this style. If they are worn, replace Gear Box them. Check that the pitman arm is Frame tight to the sector shaft. The steering wheel should start to move the pit-man arm within the approved range. If it doesn't, there is an adjustment at the gearbox to tighten up the free play. There are two adjustments: the worm bearing preload and the sector shaft mesh. Check lubricant level, and if it is low, check for a gasket leak, sector shaft seal leak or a cracked gearbox. To replace the seal the pitman arm has to be removed. If the gearbox is cracked, check with the local parts recycler.

REPLACING RAG JOINT

The rag joint is basically a vibration dampener. It keeps the chassis vibration from transferring through the steering column to the steering wheel. It can also correct a slight misalignment of the steering shaft and gearbox. Kits are available to replace the rag joint with a universal joint. Cover the left fender with a fender cover to prevent a belt buckle from mar-ring the paint fin-sh. To replace a rag joint remove the bolts that hold the coupler to the steering box and steering shaft. Loosen the steering column brackets so you can pull it back to remove the steering shaft from the coupler. Remove the coupler from the gearbox. Take the coupler to the auto parts store, and purchase a rebuild kit that includes new bolts and washers, if you want/need the experience of rebuilding, or go for a new coupler. Install the new or rebuilt rag joint in the vehicle. Excessive steering wheel free play is now corrected, if this was the problem. If not, the steering gear may need adjustment.

ADJUSTING WORM AND ROLLER

The worm and roller type of gearbox was introduced in 1926 and is still being used today. The Gemmer style worm and roller gears were a popular gearbox in Ford and Chrysler vehicles during the '30s and up to the early '60s, The roller rides on needle bearings and mounts on a shaft at the head of the sector. The rotating roller engages the worm, and there is much less friction than a worm and a fixed tooth design. Rolling friction is much smoother than sliding friction. Two Gemmer designs were popular. The 1937-52 Ford models used a two-tooth roller, and the 1953-60 models use a three-tooth roller which provides longer service life. There are several wear points, (the worm teeth and roller teeth and the upper and lower worm bushings), but they can be adjusted The sector shaft bushings and oil seal are replaceable.

ADJUSTING STEERING SHAFT BEARING PRELOAD

Sit in the driver's position, and check for steering shaft endplay by pulling/pushing on the steering wheel. If there is endplay, it must be adjusted out to set the bearing preload. Power wash the gearbox and pitman shaft area. Raise the front of the vehicle on safety stands. Remove the left front tire and wheel. Disconnect the steering linkage (drag link) from the pitman arm. If the ball on the pitman arm is worn oval, replace the pitman arm. Move the pitman arm up/down and sideways. If there is movement here and oil is leaking past the oil seal, the bushings need to be replaced. If the sector shaft is worn in this area, you are taking on an expensive repair. If pitman arm movement is not excessive, you can try a new seal. The pitman arm has to be removed to install a new seal. Check the torque on the pit-man arm nut. It can range to over 200 foot pounds on some vehicles. Tight it must be.

Slide under the vehicle on a creeper, and locate the four bolts that hold the end cover in place. Find a container to catch any oil. Remove the bolts, and carefully separate the shims using a box cutter. You will find the metal shims are easier to separate then the paper ones. Remove one shim at a time by slitting the top edge of the shim, if the horn wire is in place. Retighten the bolts, and check for end play by turning the steering wheel full right and left. Repeat this procedure until there is no noticeable endplay. Retighten the bolts. If you have a spring scale, test the bearing preload. Attach the scale to the outside rim of the steering wheel. If the pull is less than 1½ pounds, remove a shim, and retest. If the pull is more than 1½ pounds, add the necessary shims until the bearing preload is set. The steering wheel must turn smoothly from left to right.

SETTING SECTOR SHAFT MESH

Loosen the sector shaft adjusting screw in the cover. With the steering wheel in center position, tighten the adjustment screw slightly. Do not overtighten. Check amount of steering wheel free play before the pitman arm moves. Steering wheel movement can be 1½ - 2", Use the spring scale on the steering wheel rim, and if there is more than 2½ pounds pull, loosen the adjustment screw slightly. The steering wheel should turn freely from one extreme to the other without binding or stiffness. When you are satisfied with steering wheel movement, tighten the locknut on the adjusting screw. If the wheel does not turn freely, the gearbox has to be rebuilt. Recheck with the spring scale, Reconnect the pitman arm to steering linkge. Turn the ad-juster plug in until tight, and then back off to where you can fit the cotter pin. Lubricate the joint. Fill the gearbox with proper lubricant (90W hypoid gear oil). Replace the wheel and tire. Recheck the toe-in. Road test.

RECIRCULATING BALL-AND-NUT TYPE STEERING

Saginaw, a division of General Motors, pioneered this design. A ball rack carries the load, and friction forces are greatly reduced. The worm shaft has a groove machined into its surface. This precision groove is the inner half of a ball bearing race inside the ball nut rack. Another machined groove serves as the outer ball race. A set of ball bearings in guide tubes roll continuously around the shaft and ball nut. The ball bearing fit is precise. As the steering wheel rotates the worm shaft, the ball nut rack slides smoothly up and down the shaft. Teeth on the ball rack engage teeth on the inner end of the sector shaft. Although the sector teeth do not rotate, the ball nut load distributes evenly over the set of ball bearings. The result is a smoother, easier steering than the roller type gearbox. The Saginaw recirculating ball-and-nut design is the best design to date for pitman type steering boxes, and vehicle manufacturer's have used this design into the 1990s for the durability and strength in the design.

Refer to the service manual for the type of recirculating ball nut steering used in the vehicle. Note whether the adjustment calls for dis-connecting the steering linkage. Check the level of gear lube. Gear lube can seep out. Clean the area around the filler plug before removing it. The level of the gear lube should be at the base of the plug threads in the housing. Fill with 90W hypoid gear lubricant. Some steering gears do not have a filler plug. Remove the bottom bolt on the gear cover, and fill through a top bolt until lubricant flows out of the bottom hole. Some manufacturers recommend a mix of cup grease and gear lube on higher mileage vehicles.

GEAR ADJUSTMENTS

There are two adjustments to make on a recirculating ball type steering. They are both end-play adjustments because steering gear mesh is almost eliminated by the recirculating ball bearings. Raise the front of the vehicle on safety stands. It is a good idea to disconnect the steering linkage at the pitman arm to set a proper adjustment. Do not turn the steering wheel to the far right and left extremes because you may damage the ball bearings. Locate the steering wheel about one turn from full left or right position. Back off the locknut on the pitman shaft, and loosen the adjuster a few turns counter clockwise to take the mesh load off the gears. Remove the horn button from the steering wheel.

Position yourself in the driver’s seat, and push/pull on the steering wheel to check for end-play in the steering shaft. If there is excessive endplay, the steering gear may have to be re-moved for service. Measure the worm bearing preload with an inch-pound torque wrench. Attach the torque wrench to the steering wheel nut. With the steering wheel off center, read the pull required to rotate the steering shaft 1½ turns either side of center. Refer to specifications. Pull should be between 5 to 8 inch pounds. If the bearing preload is not within specifications, ad-just as follows. Loosen the steering shaft bearing adjuster locknut, and tighten or back off the bearing adjuster to bring the bearing preload within specified limits. Tighten the steering shaft bearing adjuster locknut, and recheck the preload. Turn the steering wheel slowly to either stop. The wheel should turn freely without binding or roughness. If roughness is present, the worm bearings may need replacement. If the steering wheel binds, and the steering shaft does not have a flexible coupling, loosen the steering column support. Move the steering shaft into alignment. Tighten the steering shaft support.

To adjust the pitman shaft end-play and mesh load adjustment rotate the steering wheel to center position. This places the worm and sec-tor gears in the center of their travel. Make sure the sector shaft cover bolts are tight. Using the inch pound torque wrench rotate the steering wheel back and forth through the center position. Mesh load can be 4 to 10 inch pounds depending on the type of vehicle. To adjust, loosen the sec-tor shaft adjuster screw locknut. Move the sector shaft adjuster screw as required to obtain the correct reading. Tighten the locknut while holding the adjusting screw. There must be a slight amount of play between the sector gear teeth and the ball nut teeth in the extreme right or left turn position. Do NOT try to adjust it out because the over center adjustment will become too tight. Some manufacturers suggest using a spring scale on the rim of the steering wheel instead of a inch pound torque wrench on the steering wheel nut.

RACK AND PINION STEERING

A rack and pinion steering mechanism found its way to America on the early sports cars that were imported from England during the 1950s. A pinion gear attached to the steering shaft converts the rotational motion of the steering wheel to the lateral motion of the rack. It was a simple design which meant it was cheaper to build. When the local manufacturers started to build compact front wheel drive econoboxes the rack and pinion became the choice for steering because they were lighter which meant better gas mileage. There was no need for idler arms, center links, tie rods or pitman arms. The rack and pinion is less efficient than the recirculating ball type, but there is less backlash, and it provides a better steering ‘feel’ and better overall handling. Rack and pinion steering is now the most popular choice for vehicle manufacturers.

The basic design consists of two major components: a pinion gear that is spiral cut and mounted to the end of the steering shaft and a steering bar (rack) with a toothed center section that meshes with the pinion gear. These two parts are enclosed in a steel tube. As the steering wheel is moved the pinion gear rotates and moves the toothed bar side to side. The bar is attached to the ball and socket type inner and outer tie rod ends. The inner ball joint is connected to the rack, and the outer tie rod ends are connected to the steering arm on the spindle so the vehicle moves to the right or left as the steering wheel is turned. The rack and pinion also acts as a gear reduction to reduce the amount of force needed to turn the vehicle's wheels. This reduction is the steering ratio, and it is the amount the steering wheel is turned to the degrees the tires turn. Higher ratios mean more steering wheel movement is needed to turn the tires, although, in effect, less force is required.

Most vehicles require three to four revolutions before the tire is moved from full left to full right. Lighter vehicles use a lower ratio be-cause they don't require as much force to turn, and improved steering is the result. Some vehicles include a variable ratio where the tooth pro-file of the rack and pinion is different between the center and outside of the pinion. This offers the combination of a quick response during the initial turn but a reduction in steering effort when the wheel is approaching full lock. If you find the steering wheel is starting to feel loose, and the vehicle wanders on the road instead of moving in a straight line, the problem may be in the rack and pinion. Stiff steering can be caused by lack of lubrication. Check the tires, and if they are worn on either side, the rack may be loose on the frame or the outboard/inboard tie rod joints are worn. Check these areas first. Inspect the rack housing for damage. If there are any signs of fluid leaks, they should be repaired. Re-place any torn rubber mounts, and tighten the rack in place. If the ball joints wiggle in their sockets, replace them. If the outer boot is torn, road dirt or water can enter the joint, and it may need replacing. If the inner boot (bellows) is torn, the inner ball joint may need replacing.

Check for external oil leakage at the boots, and squeeze the boot to see if it is filled with oil. If the boot is full of oil, the rack seals are leaking, and the rack is empty of lubricant. Lack of lubricant causes wear on the rack and pinion and may contribute to steering wander. Replacing the seals is only a good idea if the rack and pinion are in good condition. Seals are very difficult to source, and the price can be demanding. It is best to replace the rack with a re-built one. Steering racks are filled with oil or grease at the factory, and lubrication changes are not required. Check the service manual to see which lubricant is used. Lubricant level should be checked at every oil change.

Most rack and pinion steering systems have a pinion preload adjustment. Remove the shims one at a time. Make this adjustment with the steering turned to one side. If you make it in the straight ahead position, the steering may bind when it is turned to either side. There is also a rack guide adjustment screw that controls the play between the pinion and the rack. This screw is adjusted when there is excessive play in the steering. Loosen the locknut on the adjusting screw. Then turn the rack guide screw until it bottoms slightly. Back off the rack guide screw about 45 degrees or until the steering free play is reduced. Tighten the locknut, and road test for loose or tight steering. If the steering wheel does not center itself after turns, the steering adjustment is too right. Readjust as necessary.

These three steering types can be power assisted by hydraulics. In many new vehicles electric power steering (EPS) has replaced hydraulic power steering. The steering gear itself is a manual rack with an electric motor mounted on the steering column or rack. An electronic steering control module determines how much steering assist is required. The hydraulic power steering pump can use 8- to 10-horsepower under load, and fuel economy is one advantage when the power steering pump and hoses are re-moved. Electric power steering is also quieter because there is no pump noise and no fluid moving through the hoses and valves. There is also a difference in handling and steering.

Originally printed in Skinned Knuckles magazine, and copyrighted by SK Publishing/Skinned Knuckles Magazine. Reprinting of any portion prohibited without written permission of SK Publishing, PO Box 6983, Huntington Beach, CA 92615.

Subscriptions to Skinned Knuckles magazine is $28.00 for twelve monthly issues (within the U.S.). Contact Skinned Knuckles by mail at PO Box 6983, Huntington Beach, CA 92615; Website skinnedknuckles.net and click on Subscribe or PayPal. E-mail sk.publishing@yahoo.com, phone: 714-963-1558.