Skunned Knuckles

Skunned Knuckles Articles

by Orest Lazarowich

Rack & Pinion Power Steering

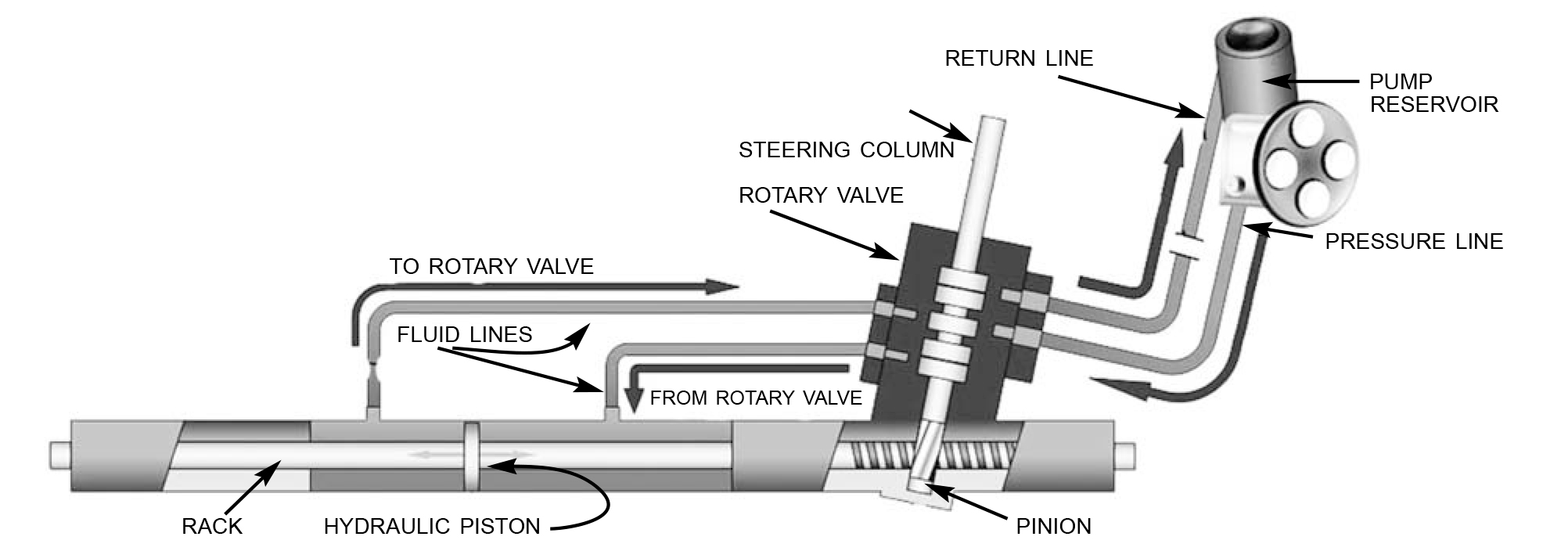

The rack and pinion power steering differs slightly from the manual rack and pinion steering. Part of the rack contains a cylinder with a piston in the middle. The piston is connected to the rack. There are two fluid ports, one on either side of the piston. A torsion bar directs the rotary valve which is connected to the steering wheel. When the steering wheel is not being turned, power steering fluid is directed around the rotary valve and out to the reservoir. The pressure is equal on both sides of the piston. As the steering wheel is turned, the torsion bar twists and rotates the rotary valve. The valve blocks the port to the reservoir, and fluid now flows through an opening to one side of the steering gear. At the same time the other side of the cylinder is vented to the reservoir. With fluid pressure to one side of the piston and none to the other, the piston moves which in turn moves the rack and causes the wheels to turn. When the steering wheel is released the rotary valve returns to neutral, pressure equalizes and the turning of the wheels stops. The power steering pump is designed to provide adequate flow when the engine is idling. As a result, the power steering pump moves much more fluid than necessary when the engine is running at faster speeds. The power steering pump contains a pres-sure relief valve to make sure that the pressure does not get too high at faster engine speeds when so much power steering fluid is being pumped.

RACK AND PINION TROUBLESHOOTING

The lack of power steering in one or both directions can be caused by a worn or damaged rotary valve. If the rotary valve housing is worn, the rotary valve will move (float) from side to side causing erratic steering. The rack will have to be removed and repaired or replaced. If the steering is heavy or hard all the time, the entire suspension system including rack and pump have to be checked for wear and possible fluid leaks. If the steering is soft (loose) and lacks feel or the vehicle wanders on the roadway, the problem can be caused by faulty MacPherson struts, tires not matched or the wheel alignment not set right. Check the steering input shaft coupling. Replace the donut style coupling, if it is starting to deteriorate. Check the metal one for rust and/or binding. If the vehicle pulls to the right or the left, check the vehicle alignment, bottom ball joints and tie rod ends for wear. Correct the suspension problems before you service the power steering pump and the steering rack.

The steering rack mounting bolts must be tight and secure. Check the rack mounting bushings. They can deteriorate and cause noise, loose steering problems and vibration. A clunking noise when the steering wheel is turned to change the direction of the wheels may be caused by a worn inner tie rod. Soft steering can be caused by a con-stricted hydraulic hose, air in the system, or a faulty power steering pump. If the steering wheel does not return to its normal neutral position after a turn, the rack and pinion maybe damaged. If the steering is heavy only during parking, check the fluid level, steering rack and power steering pump. Attach a high pressure gauge in series to the high pressure line, and check the pressure reading. Low pressure readings indicate the power steering pump has to be rebuilt or exchanged.

Check for power steering fluid leaks at the power steering pump, hoses/loose fittings and the rack assembly. The power steering hoses start to deteriorate from the inside-out, and if they feel stiff, hard or spongy, replace them. If the leaks are in the lines, replace the lines. Be very careful when tightening the fittings. The rack housing is made of aluminum, and the fittings are steel. It is very easy to strip away the threads by applying just that little bit of extra torque on the fitting. If the leak is at the fittings, check the service maal to see if O-rings or Teflon seals are used, and replace them. Power steering fluid leaks can also be caused by contaminated power steering fluid. Contaminated fluid is dark in color and may cause sticky rotary valves. A power steering stop leak product may free up sticky rotary valves, but you still have contaminated fluid in the system. Flush the system, and change the power steering fluid.

Check for leaks at the pinion seal and rack end seals. If the pinion seal shows some fluid seepage not leakage and the bellows boots do not have fluid inside them, you may be able to correct fluid seepage by changing the power steering fluid and adding a power steering conditioner to the fluid reservoir. Over time the seals and O-rings shrink and harden due to heat. The conditioner contains additives that will bring the seals and O-rings back to their original size and may prevent seepage. Squeeze the bellows boots, and if you can feel power steering fluid inside the boot, the bushings and end seals are worn. To replace these seals if they are available, the steering rack must be removed. The purpose of the bellows boots is to protect the inner tie rod from road debris. If they are ripped, they must be replaced immediately. If there are no signs of fluid leaks, check reservoir level and top up, if necessary. Check drive belt tension, and adjust or replace the belt, if it shows signs of wear.

FLUSHING RACK AND PINION STEERING GEAR

Raise the front wheels off the ground, and set the safety stands in place. Empty the reservoir of any contaminated power steering fluid. Disconnect the return hose at the reservoir, and place it into a clear plastic jug. Plug the return hose outlet at the reservoir. Fill the reservoir with the vehicle manufacturer's specified power steering fluid. Have a buddy start the vehicle, and run it at idle. While the vehicle is running keep the reservoir topped up. Do NOT run the reservoir dry. Turn the steering wheel slowly from stop to stop. When the fluid flowing from the return hose is clean, turn off the engine, and reconnect the return hose. Add a bottle of power steering conditioner to the reservoir. Top up with power steering fluid to the proper level. Start the vehicle, and check for leaks. If the power steering pump ‘whines’ or ‘growls,’ there is air caught in the sys-em.

To remove the air turn the steering wheel slowly from lock-to-lock at least ten times with the engine off. Check the reservoir, and top up with fresh fluid, if necessary. Start the engine, and rotate the steering wheel from lock to lock about 3 or 4 times. Center the steering wheel, and check the fluid level. If the fluid level has not risen and there is no foaming present, the air has been removed. If the power steering pump is still noisy, repeat the cycling procedure. If the problem returns after a day or two, carefully examine the pressure hose. A deteriorated pressure hose can allow air to enter the system. Replace the pressure hose. Check the tire pressure, and lower the vehi-cle. Road test.

REPLACING BELLOWS BOOT AND TIE RODS

The bellows boots must be replaced, if they are torn. They protect the inner tie rod and the seals from road debris. Replace them before damage is done to rack, seals and inner tie rod. It is more expensive to replace the rack and pinion than to replace the bellows boot. If the boots are not torn but you can feel power steering fluid in the boots, then the bushings and the end seals in the steering rack are worn. Check the inner and outer tie rods for wear by pushing the front tires in and out. If there is no movement at the steering wheel, one or both tie rods need to be replaced. Check the outer tie rod for freeplay. If the bellows boot moves, the inner tie rod is worn and must be replaced. If this is a high mileage vehicle 100K or more and you have to replace the inner and outer tie rods on both sides in addition to a leaking steering rack, it might be wi$er to consider a rebuilt exchange rack. The old core must be rebuildable to obtain credit.

If the rack seals are replaceable and if you can purchase a seal kit that contains all the seals and O-rings, rebuild the steering rack. However a high mileage rack will have considerable wear on the pinion gear teeth and the teeth on the rack. It is also possible that the rack shaft bearing surface that comes in contact with the bushings is worn or is bent. If so, replacing the seals and bearings will not stop the fluid leakage. The bearing on the pin-ion shaft and the pinion shaft itself may be worn. To buy all these parts separately is costly and if the rack housing is damaged, you can not repair the steering rack assembly, you are hooped. Replacement racks come in two styles: long and short racks. Long racks are complete with new inner tie rods and tie rod ends, bellows and mounts. Short racks cost less but the bellows boots and tie rods must be in good condition to be installed on the short rack. If this vehicle is a second vehicle used for short trips and the engine, power train and body have many good miles left, exchange the rack. If it is starting to two-bit you to death, buy a steering at the recycler that has come out of a low mileage vehicle. Recyclers warranty the parts about 30 days, but do you want to change the steering rack again if the one you picked was no better than the one you replaced?

To replace the bellows boots raise the front of the vehicle to a comfortable working height. Read and follow the service manual procedures. Remove the front wheels to gain some working room. Remove the cotter pin from the outer tie rod end. Loosen the castle (castellated) nut. Some vehicles use friction nuts. DO NOT reuse them. Using a large hammer hit the steering knuckle a sharp blow to separate the outer tie rod. Loosen the jam nut that is against the outer tie rod end. Remove the castle nut, and remove the outer tie rod from the steering knuckle. Count the number of turns it takes to remove the outer tie rod end off the inner tie rod. You need this measurement to locate the new tie rod end. Unscrew the jam nut. Remove the outer and inner bellows boot clamps. The inner boot clamp is not reusable. The new bellows boot may include zip ties. Remove the torn boot. Examine the inside of the boot for signs of a fluid leak. Move the inner tie rod up and down to check the rack bushing and seal for wear. If there is fluid leakage around the end of the rack shaft and you have been adding power steering fluid to the reservoir and could not find any leaks, the leak is at the rack bushing/seal and into the bellows boot. Check the other side for fluid in the bellows boot. If there is and if the inner and outer tie rod also need replacing, decide if you want to continue the repair. If both inner tie rod and outer tire rods need replacing and the rack bushings and seals are leaking, consider an exchange rack or have your original rebuilt.

If there is no fluid leak on the side with the torn bellows boot, check the inner tie rod for wear. If there is any endplay or the joint is sloppy, the inner tie rod should be replaced. Many inner tie rods use a locking pin, set screw or locking plate to prevent the tie rod from coming loose. Locate the locking device, and loosen or remove it. If it is a locking pin, pry the pin out. Do not damage the pin so you can reuse it. The space here is very limited. Check the service manual to see if it takes a special tool to remove the inner tie rod. Although you can remove the inner tie rod by holding the rack with a wrench and using another wrench on the flats of the inner tie rod it is much, much easier with a removal tool. See if your Club has one or if you can rent one. Remove the inner tie rod. Order the necessary parts.

Compare the new parts against the old parts. Read and follow the installation instructions. Use some red Locktite on the inner tie rod threads. Grease the inner tie rod end. Install the inner tie rod and locking device as per instructions. Tighten the inner tie rod to specifications. Slip the inner clamp on the bellows boot and install the bellows boot with the vent in line with the breather tube. Fit the bellows boot into the assembly grooves. Tighten the inner clamp and install the outer clamp. Screw the outer tie rod jam nut onto the inner tie rod. Screw the outer tie rod onto the inner tie rod the measured amount of turns. Fit the outer tie rod into the steering knuckle. Torque the nut to specifications to align the cotter pin. Insert a new cotter in and bend it back against the nut. Tighten the jam nut to the tie rod end. Grease the tie rod, if it has a grease fitting. Mount the wheels and lower the vehicle. Start the engine, and check the power steering reservoir, top up. Road test.

REMOVING STEERING RACK

Position the front wheels in straight ahead position. If this vehicle has a steering wheel lock, the steering wheel will center and the front wheels should be in straight ahead position. If there is no steering wheel lock, count the number of steering wheel turns from lock to lock and turn back 1/2 way to center position. Tie the steering wheel in place with the seat belt. The front wheels should be in straight ahead position with the steering wheel centered. If the steering wheel is not centered, the tie rods have to be adjusted. Crack the front wheel lug nuts loose. Disconnect the negative battery cable. Use a suction gun or turkey baster to remove all the power steering fluid from the reservoir. Raise the front of the vehicle to a comfortable working height, and set it on safety stands. Remove the front wheels.

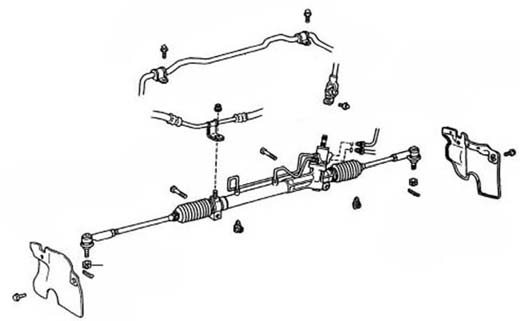

The following is general information for removing a steering rack from a vehicle that does not have an air bag restraint system. On some vehicles the subframe must be lowered to remove the steering rack while on others the steering rack is located below the subframe. Disconnect the power steering line connections, and drain the power steering fluid into a drain pan. Use a flare wrench on the fittings. Cap the lines and the openings in the rack. There may be brass seal rings or O-rings on the lines. Unbolt the pinch bolt on the steering shaft coupler. Remove the cotter pin from the castellated nuts on the tie rod ends. Remove the nuts. Deliver a sharp hit to the steering knuckle, and the tie rod will pop out or use a tie rod separator. Use a ‘pickle’ fork only if the tie rod has to be replaced.

Lower the sway bar, if necessary. Remove the power steering rack mounting bolts that connect the rack to the body. You will have to twist and turn the rack to pull it out through one of the wheel well openings and out of the vehicle. Power wash the rack clean, clean. Measure the overall length of the old rack and tie rod assembly. If the inner tie rod and outer tie rod ends are in good condition, remove them so they can be used with the short rack. Label them right and left to aid in reassembly. Order new bellows boots and clamps no matter how good you think the old bellows boots are, if you order the short rack. Order a short or long rack as needed. Order a new set of mounting bushings, if you have any doubt about the old ones. The long rack may come with the bellows boots and tie rods not assembled.

When you have the new rack in hand com-pare it with the old one. It must be the same in length and the ports have to be in the same location. Make sure the mounting holes and the pinion shaft are in the same place. Measure the distance the old rack sticks out of the housing assembly on the driver's side. Adjust the new rack to this same distance so the front wheels will point straight ahead. Install the inner and outer tie rods. Measure the overall length. It must be the same as the previous measurement. If it is different, some-thing is not right. Recheck what you have done before you start to change the length by adjusting the outer tie rod ends. Leave the outer zip tie on the bellows boots loose until the outer tie rod is in the steering knuckle. This prevents the bellows boot from being twisted. Before you install the new steering rack, tie the return line in a vertical position, and run some fresh power steering fluid through the reservoir pump and the pressure line.

Check the steering wheel position, if the vehicle that does not have lock steering. The steering wheel must be in the same position it was before the steering rack was removed. Install the new rack and bushings. Reconnect the lines, and if new O-rings or brass seal rings are supplied make sure they are installed properly and on the proper lines. Reconnect the steering shaft coupler, and bolt the rack back into place. Reattach the outer tie rods to the steering knuckles. Use new cotter pins. Torque all bolts and nuts to specifications. Tighten the outer bellows boot zip tie. Mount the front wheels. Fill the power steering pump reservoir with fresh fluid. With the engine off and the key on, turn the steering wheel from stop to stop a number of times. Check the reservoir, and add more fluid. Start the engine, and turn the steering wheel a few more times. Stop the engine, check the fluid and top off. Lower the vehicle to a level surface, and check the toe-in.

CHECKING TOE-IN

With a buddy's help and a push/pull tape measure the distance from the center of the tire tread on one front tire to the center of the tire tread on the other front tire. Measure at the back and the front of the tires at about spindle height. Check the specifications for toe-in measurement. About 1/16" is okay. To set the toe-in loosen the jam nut that is against the outer tie rods. Turn each inner tire rod in or out about 1/2 turn, and tighten the jam nut. Bounce the front end a couple of times, and recheck the measurement. Readjust, if necessary.

With a buddy's help and a push/pull tape measure the distance from the center of the tire tread on one front tire to the center of the tire tread on the other front tire. Measure at the back and the front of the tires at about spindle height. Check the specifications for toe-in measurement. About 1/16" is okay. To set the toe-in loosen the jam nut that is against the outer tie rods. Turn each inner tire rod in or out about 1/2 turn, and tighten the jam nut. Bounce the front end a couple of times, and recheck the measurement. Readjust, if necessary.

Originally printed in Skinned Knuckles magazine, and copyrighted by SK Publishing/Skinned Knuckles Magazine. Reprinting of any portion prohibited without written permission of SK Publishing, PO Box 6983, Huntington Beach, CA 92615.

Subscriptions to Skinned Knuckles magazine is $28.00 for twelve monthly issues (within the U.S.). Contact Skinned Knuckles by mail at PO Box 6983, Huntington Beach, CA 92615; Website skinnedknuckles.net and click on Subscribe or PayPal. E-mail sk.publishing@yahoo.com, phone: 714-963-1558.