Skunned Knuckles

Skunned Knuckles Articles

by Orest Lazarowich

Steering Linkage Part 1

On rear wheel drive vehicles the steering linkage consists of a number of steering rods that connect the steering gearbox to the front wheels. They convert the rotary motion of the steering wheel into angular motion of the front wheels so the vehicle can be steered to its destination. The type of steering linkage depends on whether the front axle is solid ( I-beam) or independent front suspension (IFS). The solid axle was used on many early cars and trucks and is still used on many pickups and larger trucks. The vehicle weight is carried by flat springs or coil springs.

On the solid axle the movement of one wheel is dependent on the movement of the other wheel on the axle. The steering knuckles which contain the spindles are connected to the axle by a kingpin. The steering linkage and thereby the steering knuckles are connected by a single adjustable tie rod. The connection from the steering gear box Pitman arm to the steering knuckle is through a steering rod called the drag link. When the driver turns the steering wheel the Pitman arm rotates and transfers the motion through the drag link to the steering knuckle to turn the front wheels.

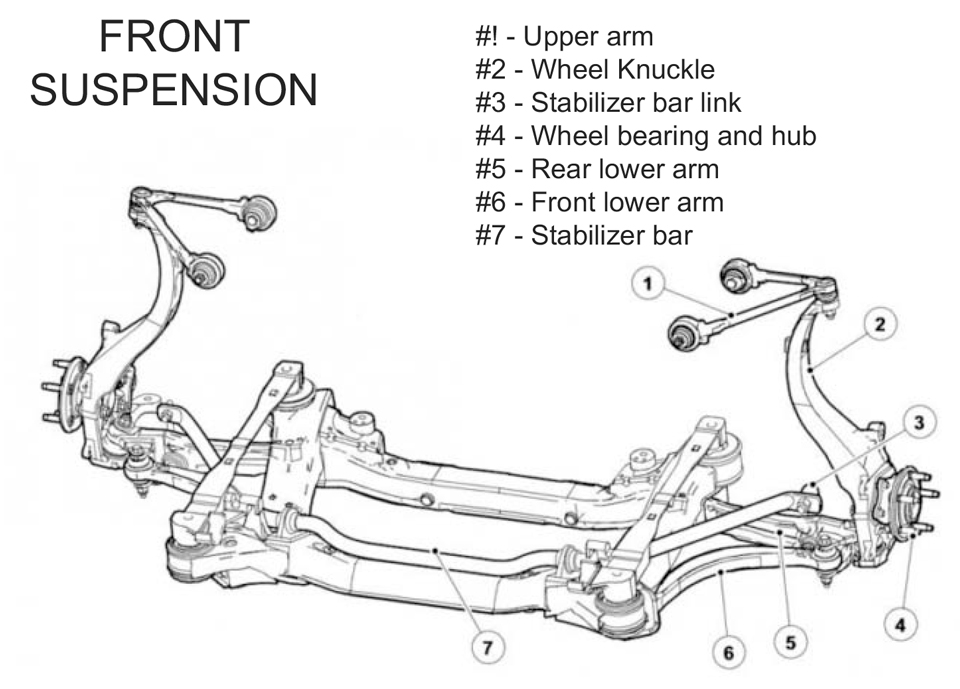

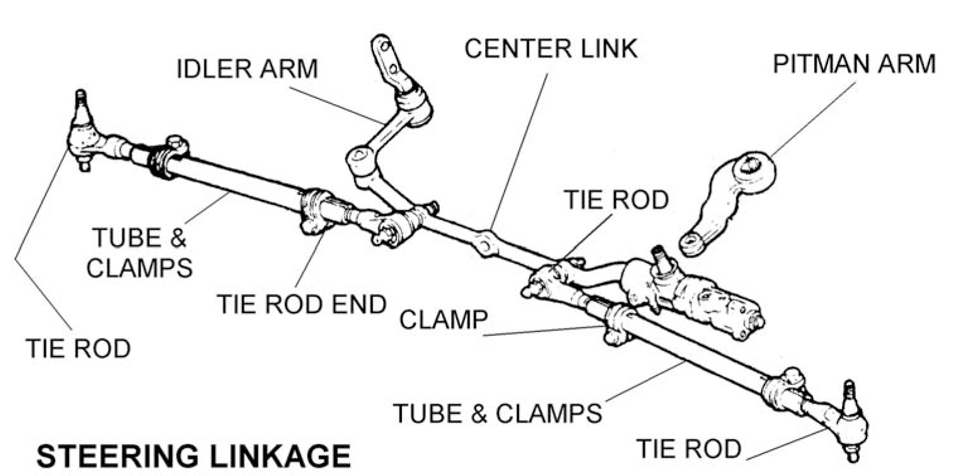

The independent suspension system is mounted on coil springs and allows each of the wheels to move independently of the other one. On independent front suspension, a steering knuckle support is located be-tween the upper and lower control arms. The steering knuckle is joined to the steering knuckle support by a kingpin. On vehicles after the mid-1950s, ball joints connect the control arms to a steering knuckle assembly which combines the steering knuckle and support into one unit. In most North American cars the steering linkage consists of three parts. The Pitman arm transmits gear movement to the left end of a relay rod or center link. An idler arm parallel to the Pitman arm is attached to the frame to support the right end of the relay rod. Two short tie rods connect the relay rod to the steering knuckle arms which transmit the movement to the steering knuckles to turn the wheels. Ball joints between the tie rods and steering arms allow steering movement even when the suspension moves up and down over rough road surfaces.

Road test the vehicle over smooth and rough road surfaces. Roll down the windows, and listen for noise (clunks, squeaking, banging) that comes from the front suspension. A vibration on the steering wheel at speeds below 50 mph might be caused by tire problems or tire balance. Tires fail be-cause of wear or road damage. If the vehicle pulls to one side or wanders in the lane, the suspension parts need to be inspected for wear. Wheels can be bent by hitting potholes. Springs can break or sag. Shock absorbers can leak and fail. The flexible connections (tie rod ends) in the steering linkage can fail because of wear. Some vehicles use rubber bushings which be-come brittle. King pin bushings wear out as do ball joints - especially the bottom one. Any banging or thumping noise when going over potholes can be caused by worn ball joints. Steering gear boxes do wear out over time. Most vehicles today are built with ‘sealed’ ball joints and tie rod ends. When the factory filled grease dries out the joint wears out. You should establish some sort of maintenance schedule that includes greasing these parts, if the parts are not worn or the rubber boots around these parts are not torn. A hypodermic needle type attachment on a regular grease gun will allow you to pierce the rubber boot and pump in the grease. Do not burst the boot. Older vehicles have grease fittings to allow lubrication. Aftermarket parts will have grease fittings when you replace original parts. Power wash all the entire front suspension parts to remove the road crud.

Before you raise the front of the vehicle on safety stands, check the steering gearbox for steering wheel free play. If the vehicle has power steering, start the engine. Wheels in straight ahead position. Stand outside the vehicle, dri-ver's window down, and turn the steering wheel. If you can move the steering wheel more than one to one and a half inches without moving the wheels, the steering gearbox may need adjustment or a rebuild. Wear safety glasses to protect your eyes and mechanic's gloves to protect your hands. Place the safety stands under the axle on solid axle vehicles. On independent suspension vehicles place the stands under the control arms so the weight is on the suspension. Block the rear wheels. Inspect the tires for irregular tread wear. Two common causes of early tire wear are improper inflation and tire misalignment caused by improper camber, toe-in and caster (alignment) adjustments. Any unusual tire wear patterns can be caused by worn or loose parts. Check the wheel lug nuts/bolts for tightness. Lug nuts/bolts should be tightened with a torque wrench. Tighten in a star pattern alternating from the lug nut/bolt to the one that is directly across from it. Torque setting for steel

wheels is 90-100 foot pounds. Recheck after 100 miles. If you heard a grinding noise coming from the front wheels, check the wheel bearings. A loose front wheel bearing will cause uneven tire wear. Spin the wheel to check for bearing roughness as it rotates. Push/pull on the tire to check for bearing side movement. Bearing side movement must be minimal ( 0.001”) and max (0.005” ). Any more than this and the bearings should be removed and inspected for cracks, pits and scoring. If bearings and bearing surfaces are okay, they can be repacked. If they are damaged, they must be replaced. Check both sides as they are exposed to the same road conditions. If ball joints, king-pins, bushings and tie rod ends are good, refer to the wheel bearing section at the end of this article.

KINGPIN CHECK

To check for kingpin wear remove the steering knuckle dust cap and the cotter key. Tighten the axle nut to remove all wheel bearing end play. Place your hands at the top and bottom of the wheel and try to rock the wheel. On a straight axle see if there is any movement at the steering knuckle. Check the other side. If there is, the kingpins and bushings need to be re-placed. On many early type independent suspensions with the coil spring between the frame and the lower control arm check the kingpins for wear at the steering knuckle and the steering knuckle support. The steering knuckle support attaches to the outer upper and lower control arms. At the top outer control arm, the steering knuckle support has an eccentric bushing and a pivot pin that adjusts the camber angle. The top inner control arm is pivoted on a cross shaft with screw-in style bushings. At the bottom outer control arm, a threaded bushing and pivot pin are used to adjust the caster angle. The inner bottom control arm is attached to the frame by a cross shaft that pivots on bushings. Rock the wheel to check for movement at the kingpin. Check the other side. If kingpin wear is evident, replace kingpins and bushings.

To check for kingpin wear remove the steering knuckle dust cap and the cotter key. Tighten the axle nut to remove all wheel bearing end play. Place your hands at the top and bottom of the wheel and try to rock the wheel. On a straight axle see if there is any movement at the steering knuckle. Check the other side. If there is, the kingpins and bushings need to be re-placed. On many early type independent suspensions with the coil spring between the frame and the lower control arm check the kingpins for wear at the steering knuckle and the steering knuckle support. The steering knuckle support attaches to the outer upper and lower control arms. At the top outer control arm, the steering knuckle support has an eccentric bushing and a pivot pin that adjusts the camber angle. The top inner control arm is pivoted on a cross shaft with screw-in style bushings. At the bottom outer control arm, a threaded bushing and pivot pin are used to adjust the caster angle. The inner bottom control arm is attached to the frame by a cross shaft that pivots on bushings. Rock the wheel to check for movement at the kingpin. Check the other side. If kingpin wear is evident, replace kingpins and bushings.

Remove the front wheels. Use a pry bar, and check for wear at the steering knuckle pivots at the upper and lower control arms. Check for wear at the outer upper and lower pivot pins of the control arms. If there is excessive wear at the upper or lower pivot pin, it will be difficult to set the camber and caster wheel alignment adjusters to specifications. Camber is the tilting angle of the front wheel. If the camber is out of adjustment, tire wear will be on the inside or outside edge of the tire. It also causes excessive wear of suspension parts. Caster is the tilting of the uppermost point of the steering axis. If the caster is out of adjustment, the vehicle will wander and/or pull to the side. Caster has little effect on tire wear. Check for wear or binding at the inner control arm cross shafts. If there is minimal wear at the control arm pivot points but the kingpin wear is excessive, start with replacing the king-pins. Repeat this test on the other front wheel.

BALL JOINT CHECK

Ball joints are flexible joints that allow the suspension to move up and down and side to side usually in a full 360-degree rotation. During the road test, a banging sound coming from vehicle's front corners is usually caused by worn ball joints. With the safety stands under the lower control arms you can check the bottom ball joint for wear. Look for any signs of rust, a torn grease boot or grease leakage around the ball joint. Grab the top and bottom of the tire, and rock the tire. There should be little or no movement, if the joint is okay. Any noise or excessive movement coming from the bottom ball joint remove the wheel, and visually inspect the bottom ball joint. Some ball joints have a grease fitting that serves as a wear indicator. When the ball joint is new the base protrudes about 1/16 inch from the rubber cover. When worn the base is flush with the cover. To check the top ball joint you have to move the safety stand under the front cross member to put a load on the top ball joint. If the bot-tom ball joint needs replacing, it is easier to check the upper ball joint when the lower control arm is disconnected.

CHECK TIE RODS

Wheels and tires should stay straight when you drive unless you turn the steering wheel. Loose tie rod ends will cause the steering to wander during a road test. Front alignment will be off, and tire wear will be uneven. The tie rod end is a ball and socket. It can be the half-ball type or the full ball design. With your hands at the 3 and 9 clock positions move the tire in and out. If there is any play in the wheel, it could be the outer tie rod ends. Remove the wheel, and examine the tie rod end. If the boot is torn, road dirt has probably worn the joint. Move the steering knuckle in and out. If the tie rod does not move, the tie rod end is worn and must be replaced. Check the other side. On single tie rod styles used with straight axles replace the tie rod ends and adjust the drag link. On independent suspension there are two tie rods with adjustable tie rod ends. Check the outer tie rod ends, and then slide under the vehicle and check for wear at the center link (where the tie rod arms attach and at the idler arm and the Pit-man arm connection). Grab the center link, and move these parts up and down. Excessive up and down movement at any of the connections means replacement of the worn parts. Make sure the Pit-man arm nut is tight. There should be a lock-washer under the nut. On vehicles where a ball joint is part of the Pitman arm, the Pitman arm has to be replaced, if the ball joint is worn out.

SOLID AXLE WITH FLAT SPRINGS

Raise the vehicle on safety stands placed under the front axle and block the rear wheels. Remove the wheels. Inspect the spring bushings, pins and brackets (shackles) for wear by inserting a pry bar between the spring and the frame and moving the bar up and down. Bushings wear at different rates, but noise, poor road handling (wandering), and tire wear, if the kingpins are okay, indicate that the bushings and pins need replacing. Bushings can be metal or rubber and usually wear down because of friction and stress. Spray with silicone to contain rubber squeaks. Check the spring for broken leaves, broken center bolt and sagging condition. Loose U-bolts can break the center bolt or the leaves. If only one leaf is broken, it can be re-placed. If two or more leaves are broken, the entire spring assembly should be replaced. If one assembly is being replaced, the other side should also be replaced. U-bolts should always be replaced. Spring repairs must be fixed before kingpin replacement. You must move the safety stands behind the front spring rear brackets to service the springs. The following procedure is for kingpin and bushing replacement when the spring assembly does not need service. The bushings are driven into the steering knuckle. The safety stands stay under the axle.

This is a weekend project so order the necessary parts in advance. Have the parts 'in hand' before you start any work. Some vehicles with wood spoke wheels do not have front wheel brakes so there is no brake drum (1928 ACME truck). You remove the wheel hub. On vehicles using front brakes back off the brake adjustment so the drum can be removed. Remove the wheel bearing dust cap, cotter key and spindle nut. As you pull the brake drum off, catch the outer bearing in a cloth; do not drop the bearing on the floor. Wheel bearings can be the ball bearing type or the tapered roller style. If a previous test indicated wheel bearing problems, inspect the bearings, and grease or replace them and the seal before re-assembly. Wipe the spindle clean of any grease. Remove the bolts that hold the brake backing plate to the steering knuckle. Do not remove the brake hose but tie the backing plate out of the way. Wrap some masking tape around one end of the tie rod, and identify it as either the left or right hand end to aid in assembly. To disconnect the tie rod from the steering knuckles remove the cotter key and the nut. If the tie rods are worn and need replacing, you can use a ‘pickle’ fork and a hammer to separate them. A ‘pickle’ fork can damage a good grease boot on a tie rod end that is still serviceable. Use a tie rod puller tool or back up one side of the steering knuckle with a hammer. With another hammer hit the steering knuckle around the tie rod shaft to break the taper fit free. Disconnect the drag link at the steering knuckle. Remove the cotter key and then the ball plug. There is a special socket for this, but a large flat screwdriver will also work. Remove the seat and the spring and pull the drag link off the steering knuckle. Examine the ball stud; if there is a flat spot, it will cause the steering to bind when the wheels are turned. Replacement ball studs are available for some vehicles.

REPLACING KINGPINS

Order a kingpin kit and right and left tie rod ends. If available, purchase a kingpin/bushing kit that includes pre-sized bushings. Do not start any work until you have the replacement parts ‘in hand’. Wear safety glasses. Remove the kingpin locking bolt nut, and use a punch to drive the bolt out. Notice that it is tapered and has a flat side that locks against the kingpin. New bolts come with a kingpin kit. On some vehicles, there is a grease cap seal at the top and bottom of the steering knuckle. The cap is made of soft material so strike it with a sharp chisel to get under the lip and then remove the cap. Drive the kingpin downwards to remove it. On others, the cap is part of the kingpin, and the kingpin is driven upwards to remove it from the axle. Spray some penetrating oil directly into the locking pin hole. Allow some time for the penetrating oil to do its job. Drive the kingpin up or down using a heavy hammer and a punch. If the kingpin moves after a number of hits, apply more penetrating oil. Keep hitting and applying penetrating oil until the kingpin comes out. You should be this lucky. If the kingpin does not move after re-peated hammer blows, it may be necessary to heat the axle or remove the axle and use a hydraulic press to press the old kingpins out.

With the steering knuckle free of the axle remove the grease fittings, and clean the steering knuckle. Clamp the steering knuckle in a large bench vise. Use a bushing driver or sockets of the correct size to drive out the old bushings. Install the new bushings so the holes in them line up with the grease fitting openings. Clean up any burrs on the outside of the bushings. The new kingpin should slide into both bushings on its own weight. If the kingpin does not fit, use a reamer or a brake cylinder hone to slightly en-large the bushing allowable clearance (0.001” to 0.003” ). You want to push the pin in by hand. It should not drop out by gravity. If using a brake cylinder hone, keep it and the drill in a straight line, and use WD40 to flush out the cuttings. Do not push the spinning stones all the way through because they and the spring loaded arms will get damaged. If you have no way to remove/ replace the bushings or hone the bushings, if necessary, use the services of a machine shop. Clean the axle kingpin hole with emery cloth or the hone to remove any corrosion. Hand grease the bearing. Set the steering knuckle on the axle with the bearing on the bottom and the writing facing the top. Check for any up and down movement of the steering knuckle. If there is any, install as many shims as possible to minimize this movement. Lightly grease the kingpin so it will slide into the steering knuckle. Keep the notch in the kingpin lined up with the hole in the axle. Tap the kingpin down until you can insert the locking bolt with the flat side to the kingpin. Install the spring washer, and tighten the nut. Install a new grease fitting, and lubricate the bushings. Same service to the other side.

REPLACING TIE ROD ENDS

Hold the tie rod in a vise. Measure the distance from the end of the thread on the tie rod end to the adjusting sleeve with a steel ruler. Write this measurement down. Loosen the tie rod clamping bolt on the adjusting sleeve. Unscrew the tie rod end. You can count the number of turns it takes to remove the tie rod end. Be ac-curate to ¼ turn. Write down the count. Doing this will make sure the toe-in adjustment stays the same. Apply anti-seize compound to the threads of the new tie rod end. Screw the new tie rod end into the adjusting sleeve the exact number of turns that you counted. Check the thread distance with the ruler. Tighten the clamp bolt. Remove/replace the other tie rod end. Brush off any rust, and paint the tie rod, tie rod ends, axle, steering knuckles and springs with black enamel. Connect the tie rod to the steering knuckles. Generally the clamp bolts of the adjusting sleeve face to the rear of the vehicle. Lubricate the tie rod ends until the boot is full of grease. Paint the back of the backing plates, and bolt them to the to the steering knuckles.

WHEEL BEARINGS

The front wheel bearings support their share of the vehicle weight. With drum brakes a worn front wheel bearing will cause the brake shoes to drag and the wheel bearing lubricant will leak past the inner brake drum seal onto the brake shoes. On disc brakes you may feel a pedal pulsation when applying the brakes. With the front of the vehicle raised on safety stands re-move the wheel. There are two complete sets of bearings per wheel, and they should be replaced as pairs. On tapered roller wheel bearings there is a tapered inner and outer bearing that rides on the inside taper of the inner and outer wheel bearing race which is pressed into the brake drum hub. Back off the star adjuster or adjusting bolt to move the brake shoes away from the drum which makes the drum come off easier. If the vehicle has front caliper brakes, remove the caliper bolts or sliding pins, and hang the caliper out of the way with some wire. Remove the dust cap by prying it off with a large screwdriver. Straighten the cotter pin, and remove it. Unscrew the castle nut. Pull the brake drum/disc forward, and catch the small outer bearing and washer in your hand or into a shop rag. Pull the inner bear-ing off the spindle, and move the brake drum/disc to the workbench. Wipe the spindle clean of grease, and inspect for wear and/or cracks. Remove the other drum/disc and mark it left or right. Place it on the workbench.

Work on each brake drum/disc separately. Pry out the seal, and remove the inner bearing. Wash the bearings, and dry with compressed air. Inspect the bearings. Rotate the cage assemblies on your fingers by hand NOT air, and look for any scoring, chatter marks or obvious wear pat-terns. Any blue metal is because of overheating due to lack of lubrication. Clean all the old grease out of the hub and off the spindle. Check the bearing races for similar wear and damage. If there is no damage, the bearings can be repacked with fresh wheel bearing grease and reused. Install a new seal. Any sign of damage or wear on the bearing race or the bearing and the bearing assembly has to be replaced. Wear patterns on the old race and bearing match so new bearings must be installed as a set. Installing only a new bearing will shorten the life of the bearing assembly. Order new bearings and the grease seals.

To remove the bearing’s races you will find two notches inside the hub just behind the races, 180 degrees apart. They are in this position so you can use a hammer and a pin punch to drive out the race by alternately hitting the race at one notch and then the other. If you have the use of a hydraulic press and a short piece of pipe with a diameter just shy of the bearing race, you can press the races out. Before you drive the race in make sure its land is clean and free of burrs. Keep the new bearing and the race to-ether as a set. The new bearing race is installed with the taper facing up. Do not install it backward. You can use a bearing race and seal driver kit or a hydraulic press to install the new races. Be sure the race is going in square and is tight against the land when you are done. A hammer and brass punch can be used to drive the races in. You can also take the hub to a machine shop and let them do the removal/replacement of the bearing races.

Lubricate the old or new tapered roller bearings with wheel bearing grease using a packer or by hand. When packing by hand, start with about a golf ball sized mound of grease in the palm of the left hand, if you are right handed. Scrape the grease up into the wide open end of the bearing until grease appears at the top of the bearing cone. Be sure the grease is thoroughly worked into the cage and the rollers. Pack the inside of the hub cavity with grease. Coat the inside of the dust cap with a light coating of grease to prevent rust caused by condensation. Lightly grease the bearing races. Install the inner bearing and then the grease seal with the lip facing in-ward. Apply a light coating of non-hardening sealer to the outer edge of the seal, and drive the seal inward with a seal driver or block of wood. The seal should be flush with the top surface of the hub. Install the brake drum assembly back over the spindle. Install the outer bearing, washer and adjusting nut on the spindle. Use a torque wrench, and tighten the adjusting nut to 50-foot pounds while turning the brake drum/rotor assembly to seat the bearing. Back off the adjusting nut one full turn and re-torque to ten-foot pounds while turning the brake drum/rotor. Back off the adjusting nut ¼ turn, and install the new cotter key. Bend one end of the cotter key over the spindle and the other over the adjusting nut. End play measured with a dial indicator should be between 0.001” and max 0.005”. Readjust, if necessary. Install the dust cap. Adjust the brake shoes. In-stall the caliper. Lubricate the caliper pins, sleeves and bushings with brake grease during installation. Make sure the rotor spins freely. Install the tire and wheel. Happy motoring.

Originally printed in Skinned Knuckles magazine, and copyrighted by SK Publishing/Skinned Knuckles Magazine. Reprinting of any portion prohibited without written permission of SK Publishing, PO Box 6983, Huntington Beach, CA 92615.

Subscriptions to Skinned Knuckles magazine is $28.00 for twelve monthly issues (within the U.S.). Contact Skinned Knuckles by mail at PO Box 6983, Huntington Beach, CA 92615; Website skinnedknuckles.net and click on Subscribe or PayPal. E-mail sk.publishing@yahoo.com, phone: 714-963-1558.